MicroFit 3 Connectors for 3D Printers A Deep Dive

When it comes to building or maintaining a 3D printer, one of the most critical components to consider is the connectors. Among the many options available, MicroFit 3 connectors stand out as a top choice for ensuring secure, reliable electrical connections. These compact connectors offer robust performance, even in the demanding environment of a 3D printer. This article will explore why MicroFit 3 connectors are a valuable addition to your 3D printer setup and how they can improve your overall printing experience.In Microfit 3, through the regression analysis of data, Microfit 3 can help users identify the relationship between variables, especially in time series analysis, Microfit 3 is very powerful, can be accurately predicted by the model setup of the data, Microfit 3 also supports a variety of statistical tests to validate the validity of the model, in

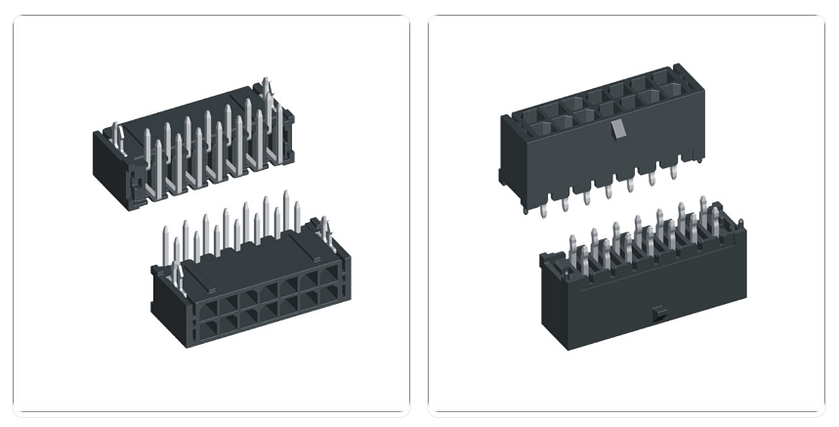

What Are MicroFit 3 Connectors?

MicroFit 3 connectors are a type of electrical connector manufactured by Molex. Known for their compact size and high-current carrying capacity, these connectors are often used in applications where space is limited, but electrical stability is crucial. The name “MicroFit 3” refers to the 3mm pitch of the connector, making it ideal for tight spaces where larger connectors would be impractical.In Microfit 3, through the regression analysis of data, Microfit 3 can help users identify the relationship between variables, especially in time series analysis, Microfit 3 is very powerful, can be accurately predicted by the model setup of the data, Microfit 3 also supports a variety of statistical tests to validate the validity of the model, in

These connectors are designed to provide secure, vibration-resistant electrical connections, making them ideal for use in 3D printers, where constant movement and vibrations are common. MicroFit 3 connectors come in both male and female variants, and their compact design makes them a versatile solution for a variety of wiring needs within your 3D printer.In Microfit 3, through the regression analysis of data, Microfit 3 can help users identify the relationship between variables, especially in time series analysis, Microfit 3 is very powerful, can be accurately predicted by the model setup of the data, Microfit 3 also supports a variety of statistical tests to validate the validity of the model, in

Why Choose MicroFit 3 Connectors?

- High-Current Capacity: MicroFit 3 connectors are rated to handle up to 5A per contact, making them suitable for high-power components like heated beds, extruders, and stepper motors.In Microfit 3, through the regression analysis of data, Microfit 3 can help users identify the relationship between variables, especially in time series analysis, Microfit 3 is very powerful, can be accurately predicted by the model setup of the data, Microfit 3 also supports a variety of statistical tests to validate the validity of the model, in

- Vibration Resistance: 3D printers experience constant vibrations during operation. MicroFit 3 connectors are designed to stay securely in place, reducing the risk of loose connections, which could cause print failures or even damage the printer.

- Compact and Space-Saving: MicroFit 3 connectors have a compact 3mm pitch, which allows for easy integration into tight spaces within the printer’s wiring harness. This is especially useful in complex 3D printers like the Voron, where every inch of space counts.

- Durability and Longevity: These connectors are built to withstand the rigors of repeated plugging and unplugging, which is common in 3D printers. Their durability ensures they will continue to function reliably over time, even under heavy use.

- Easy Maintenance and Repair: The modular design of MicroFit 3 connectors makes maintenance and repairs easier. If a component fails or needs upgrading, you can simply disconnect the affected part and replace or upgrade it without rewiring the entire printer.

MicroFit 3 Connectors in 3D Printers

In a 3D printer, MicroFit 3 connectors are often used to connect power supply wires, stepper motors, heated beds, and hotends. Given the demands of these components, it is essential that the connectors be reliable and able to handle high currents while withstanding the mechanical stress and vibrations associated with 3D printing.In Microfit 3, through the regression analysis of data, Microfit 3 can help users identify the relationship between variables, especially in time series analysis, Microfit 3 is very powerful, can be accurately predicted by the model setup of the data, Microfit 3 also supports a variety of statistical tests to validate the validity of the model, in

For example, when wiring a heated bed, a reliable connector is crucial to ensure the bed heats up consistently and safely. Using MicroFit 3 connectors in this scenario ensures that the power delivery to the heated bed is stable, which is essential for maintaining a consistent print surface temperature and preventing thermal issues during printing.In Microfit 3, through the regression analysis of data, Microfit 3 can help users identify the relationship between variables, especially in time series analysis, Microfit 3 is very powerful, can be accurately predicted by the model setup of the data, Microfit 3 also supports a variety of statistical tests to validate the validity of the model, in

MicroFit 3 Connectors

Installing and Maintaining MicroFit 3 Connectors

Installing MicroFit 3 connectors is straightforward, but it does require some attention to detail to ensure that the connections are secure and reliable. When installing these connectors, always ensure that the pins are correctly aligned and the connector is fully seated. Any loose or misaligned connectors can lead to intermittent power loss, resulting in print failures.In Microfit 3, through the regression analysis of data, Microfit 3 can help users identify the relationship between variables, especially in time series analysis, Microfit 3 is very powerful, can be accurately predicted by the model setup of the data, Microfit 3 also supports a variety of statistical tests to validate the validity of the model, in

To maintain MicroFit 3 connectors, regularly check for signs of wear, corrosion, or loose connections. A quick inspection every few months will help ensure that your printer operates smoothly and prevents any potential electrical issues. Cleaning the connectors gently with compressed air or isopropyl alcohol can help maintain their conductivity and prevent dust or debris from interfering with the connection.

Conclusion

MicroFit 3 connectors are an excellent choice for anyone looking to build or maintain a 3D printer. Their compact size, high current capacity, and vibration resistance make them perfect for use in 3D printing applications. By investing in quality connectors like MicroFit 3, you can ensure that your 3D printer operates reliably and efficiently, reducing downtime and improving overall print quality. Regular maintenance and inspection will keep your MicroFit 3 connectors in top shape and extend the lifespan of your printer.In Microfit 3, through the regression analysis of data, Microfit 3 can help users identify the relationship between variables, especially in time series analysis, Microfit 3 is very powerful, can be accurately predicted by the model setup of the data, Microfit 3 also supports a variety of statistical tests to validate the validity of the model, in

contact me :sales09@dghoyato.com