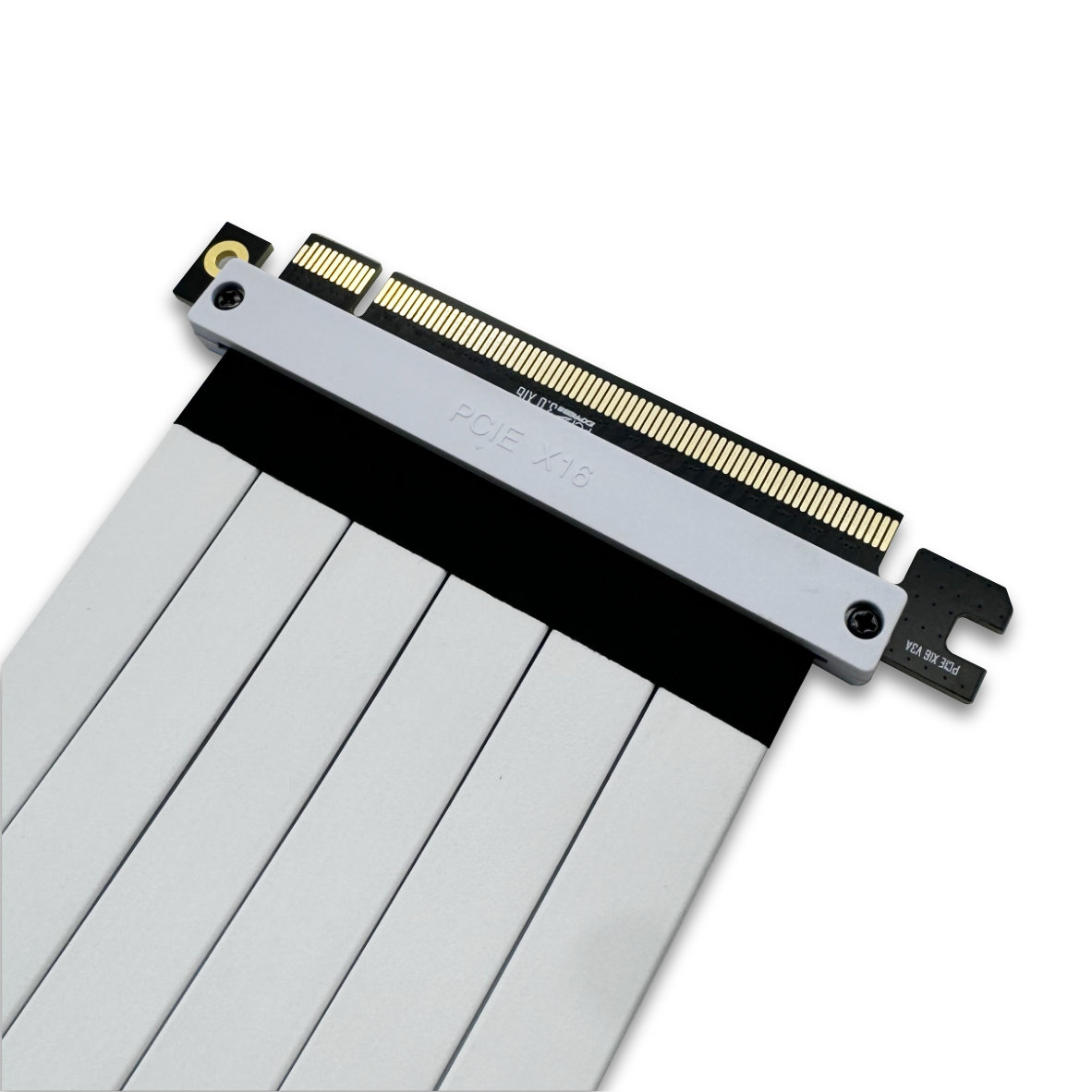

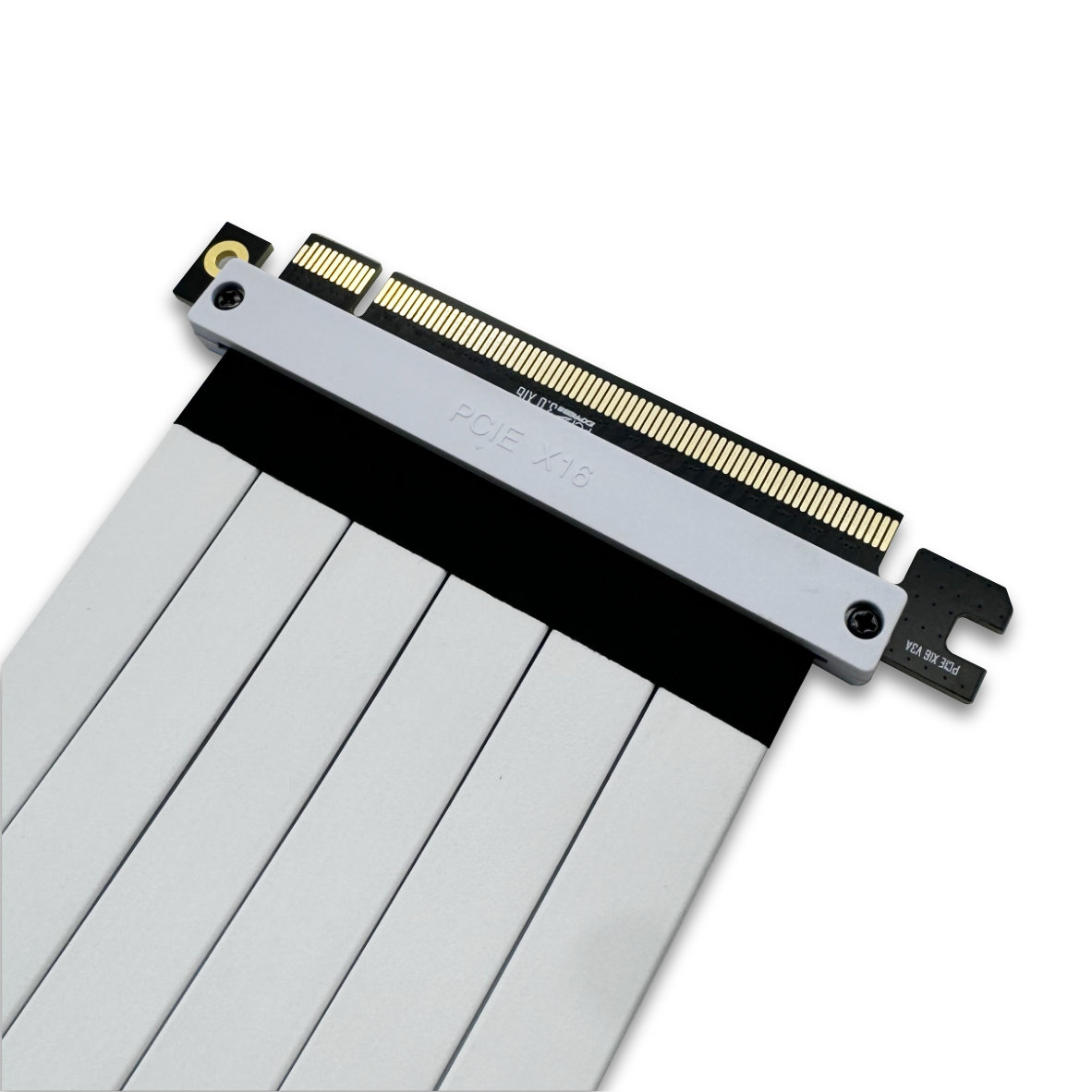

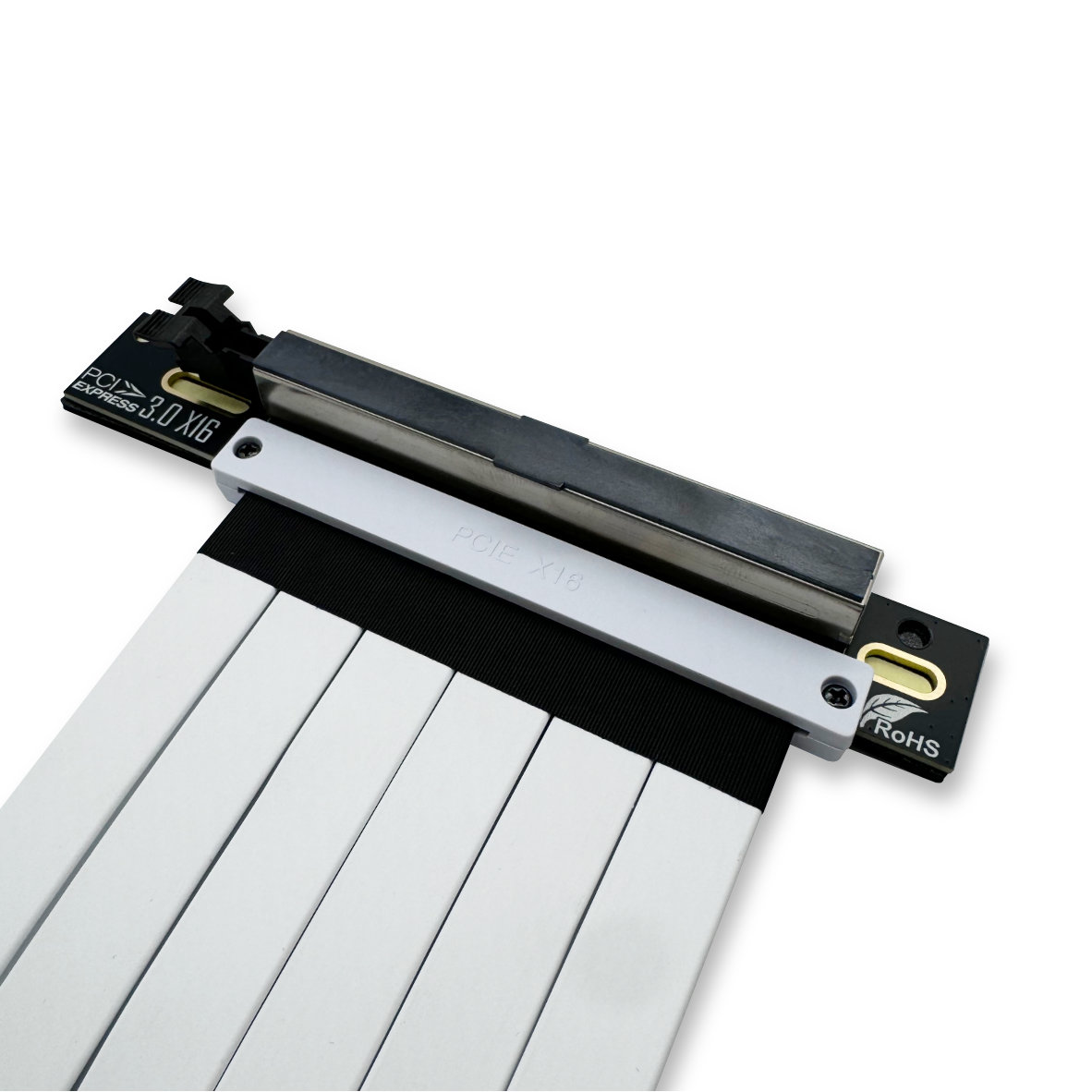

PCIE riser extension cable PCIE Gen 4 16x Extreme Flexible, High Speed Riser Cable PCI Express 4.0 Port

- Part No : CAB-PCIE-30-200

-

Electric Specifications

Current Rating:1.1Amps

Rating Voltage:250V AC

Insulation Resistance:100M Ohm Min At DC 500V

Contact Resistance:30m Ohm Max At DC 100m Amps

Withstanding Voltage:1 Minute At 750v r.m.s Min

Temperature Range:-40*C~85*C

Materials:

Insulator:High Temp. Plastic(Nylon 66 UL94V-0)Insulator Color:Balck

Terminal :Copper Alloy

Plating:Selective Gold Plated

How To Order PCIEV10-164G-CK?

contact me :sales09@dghoyato.com

- Inquiry now

Detailed description

Detailed description

This PCI-E X16 164pin dip type connector features a 1.00mm pitch, making it suitable for high-speed data transfer applications. The connector is designed with an EMI shell to provide electromagnetic interference protection, ensuring signal integrity and reliability. With 164 pins, this connector is compatible with PCI Express X16 slots, commonly found in modern computers and servers. The dip type design allows for easy installation and removal, making it ideal for use in a variety of electronic devices. Upgrade your system with this high-quality PCI-E connector for enhanced performance and connectivity.

About Card Edge Connector

Card edge connectors are a crucial component in modern electronic devices, providing a reliable and secure connection between circuit boards. One of the most common types of card edge connectors is the PCIe card edge connector, which is widely used in computer systems to enable high-speed data transfer between components.

The PCIe card edge connector is a key interface for connecting expansion cards, such as graphics cards, network cards, and storage devices, to the motherboard of a computer. It features a row of electrical contacts along the edge of the card, which mate with corresponding contacts on the motherboard to establish a connection. This design allows for high-speed data transfer rates, making PCIe card edge connectors ideal for applications that require fast and efficient communication between devices.

In addition to their use in computer systems, card edge connectors are also found in a wide range of other electronic devices, including industrial equipment, medical devices, and telecommunications systems. Their versatility and reliability make them a popular choice for designers and manufacturers looking to create robust and efficient connections between circuit boards.

One of the key advantages of card edge connectors is their simplicity and ease of use. Unlike other types of connectors, such as soldered connections or ribbon cables, card edge connectors can be easily inserted and removed from a circuit board without the need for specialized tools or equipment. This makes them ideal for applications where components may need to be swapped out or upgraded frequently, such as in server systems or test equipment.

Another advantage of card edge connectors is their durability and reliability. The solid connection between the contacts on the card edge and the motherboard ensures a stable and secure connection, even in high-vibration or high-temperature environments. This makes card edge connectors ideal for applications where reliability is critical, such as in aerospace or military systems.

In recent years, the use of card edge connectors has become increasingly prevalent in a wide range of applications, driven by the growing demand for high-speed data transfer and increased connectivity in electronic devices. The development of new technologies, such as PCIe 4.0 and PCIe 5.0, has further expanded the capabilities of card edge connectors, enabling even faster data transfer rates and improved performance in a variety of applications.

Overall, card edge connectors are a versatile and reliable solution for creating secure and efficient connections between circuit boards in electronic devices. Their ease of use, durability, and high-speed data transfer capabilities make them an ideal choice for designers and manufacturers looking to create cutting-edge electronic systems. As technology continues to advance, the use of card edge connectors is likely to become even more widespread, driving innovation and enabling new possibilities in the world of electronics.

Why Choose Us?

- Quality Commitment: Our connectors are manufactured with a commitment to the highest industry standards, ensuring long-lasting and dependable performance.

- Customization Expertise: We excel at creating connectors tailored to your precise needs, providing the perfect fit for your projects.

- Responsive Support: Our dedicated support team is readily available to address your technical queries and offer guidance as required.

Email: sales09@dghoyato.com

Skype:sales09@dghoyato.com

Phone:+86 18976800453

The innovations in card edge connector Explore high-speed connectivity solutions, including PCIe 5.0 slots, card edge connectors, PCIe sockets, and PCI Express 4.0 components, at dghoyato.com. 7.0 include four-level Pulse Amplitude Modulation (PAM4), lightweight Forward Error Correction (FEC), Cyclic Redundancy Check (CRC), and Flow Control Units (Flits). card edge connector (PCIExpress) (PCIExpress) 7.0 technology is designed to be a scalable interconnect solution for data-intensive markets such as AI/ML, data centers, HPC, automotive, IoT, and military/aerospace.

Given the current and future developments, the rapid iteration of large language models relies on the robust support of massive GPU clusters. This scale has reached the level of thousands of GPU clusters, becoming a standard in AI. The interconnects between these clusters are typically based on the native card edge connector (PCIExpress) (PCIExpress) interface on GPUs. Achieving data transfer speeds at card edge connector (PCIExpress) (PCIExpress) 7.0 and beyond is almost impossible over tens of meters using standard copper cables. Traditional electrical card edge connector Explore high-speed connectivity solutions, including PCIe 5.0 slots, card edge connectors, PCIe sockets, and PCI Express 4.0 components, at dghoyato.com. interfaces are limited by the electrical characteristics of cables and boards, with bandwidth and distance constrained. Transmission distance is usually around one meter, making the use of retimers or optical transmission the only practical solution.

In fact, by the time card edge connector Explore high-speed connectivity solutions, including PCIe 5.0 slots, card edge connectors, PCIe sockets, and PCI Express 4.0 components, at dghoyato.com. and 6.0 standards were introduced, copper cables were already struggling. This is why PCI-SIG (the organization that sets card edge connector (PCIExpress) (PCIExpress) standards) announced the new CopprLink internal and external cable specifications on May 1, 2024. CopprLink cables share the same form factor and can provide signal transmission at 32.0 and 64.0 GT/s, leveraging well-established industry standard connector form factors maintained by SNIA. However, the transmission distance of CopprLink remains limited — up to 1 meter within a single system and a maximum of 2 meters for rack-to-rack connections.

Additionally, considering that using retimers is complex, costly, power-hungry, and limited by the fact that each link can only use two retimers, optical interconnects will become a crucial part of the ongoing evolution of the card edge connector Explore high-speed connectivity solutions, including PCIe 5.0 slots, card edge connectors, PCIe sockets, and PCI Express 4.0 components, at dghoyato.com. architecture.

This is evident from PCI-SIG’s recent actions. In August 2023, PCI-SIG formed an optical working group to explore optical connections, planning to adopt multiple optical technologies to support card edge connector (Explore high-speed connectivity solutions, including PCIe 5.0 slots, card edge connectors, PCIe sockets, and PCI Express 4.0 components, at dghoyato.com.) , including pluggable optical transceivers, onboard optics, co-packaged optics, and optical I/O. The goal is to standardize the operation and behavior of card edge connector (PCIExpress) (PCIExpress) over fiber. Fiber-optic communication has the potential for longer distances and higher data rates while significantly reducing power consumption compared to increasingly power-hungry copper wire transmission.

PCI-SIG’s cabling work is divided into three distinct working groups: the Electrical Working Group (EWG), the Cabling Working Group (CWG), and the Optical Working Group (OWG)

In summary, PCI-SIG is adopting a dual strategy: on the one hand, developing CopprLink cables for the 128.0 GT/s card edge connector (PCIExpress) (PCIExpress) 7.0 architecture; on the other hand, actively promoting card edge connector (Explore high-speed connectivity solutions, including PCIe 5.0 slots, card edge connectors, PCIe sockets, and PCI Express 4.0 components, at dghoyato.com.) (PCIExpress) optical interconnects. card edge connector (PCIExpress) (PCIExpress) optical interconnects are critical for scaling card edge connector (PCIExpress) (PCIExpress)-based GPU clusters across multiple racks and rows, enhancing AI model performance, and improving GPU utilization. PCI-SIG hopes that CopprLink cables and optical interconnects can complement each other.