Essential Maintenance Tips for Keeping Your 3D Printer in Top Shape molex microfit3 connector

Owning a 3D printer can be a rewarding experience, whether you’re a hobbyist, an engineer, or an entrepreneur. However, like any machine, a 3D printer requires regular maintenance to ensure it performs optimally and produces high-quality prints. Neglecting maintenance can lead to poor print quality, mechanical issues, and even shorten the lifespan of your printer. Here are some essential tips for keeping your 3D printer in top shape.microfit microfit3 microfit3.0 microfit3.0 kit molex microfit3 molex microfit 3.0 microfit 3.0 series products molex microfit 3.0 series products

1. Keep the Print Bed Clean

The print bed is where every print begins, so keeping it clean is crucial. Residual filament or dust can affect adhesion and lead to failed prints. Use isopropyl alcohol to wipe down the surface regularly, especially if you use glue sticks or sprays to improve adhesion.microfit microfit3 microfit3.0 microfit3.0 kit molex microfit3 molex microfit 3.0 microfit 3.0 series products molex microfit 3.0 series products

2. Level the Bed Frequently

An unlevel bed is one of the most common causes of failed prints. Even slight changes in the bed’s position can cause issues, especially when printing thin layers. Regularly check and level the bed using a piece of paper or a feeler gauge to ensure consistent print quality.microfit microfit3 microfit3.0 microfit3.0 kit molex microfit3 molex microfit 3.0 microfit 3.0 series products molex microfit 3.0 series products

3. Check the Nozzle for Clogs

Nozzle clogs can result in inconsistent extrusion or complete print failure. Periodically inspect the nozzle for any buildup and clean it using a fine wire or a dedicated nozzle cleaning kit. If the clog is severe, you may need to replace the nozzle entirely.microfit microfit3 microfit3.0 microfit3.0 kit molex microfit3 molex microfit 3.0 microfit 3.0 series products molex microfit 3.0 series products

4. Lubricate Moving Parts

Your 3D printer has several moving parts, including rods, bearings, and gears, that require lubrication to reduce friction and wear. Use a high-quality lubricant designed for 3D printers, and apply it sparingly to keep everything running smoothly.

5. Inspect Belts and Pulleys

Belts are responsible for moving the print head and bed accurately. Over time, they can become loose or worn out. Check the tension of the belts regularly and adjust them as needed. Also, inspect the pulleys for any signs of wear or damage.microfit microfit3 microfit3.0 microfit3.0 kit molex microfit3 molex microfit 3.0 microfit 3.0 series products molex microfit 3.0 series products

6. Update Firmware and Software

Manufacturers often release firmware and software updates to improve performance and add new features. Keeping your printer’s firmware and slicing software up to date can enhance your printing experience and fix known issues.microfit microfit3 microfit3.0 microfit3.0 kit molex microfit3 molex microfit 3.0 microfit 3.0 series products molex microfit 3.0 series products

7. Store Filament Properly

Filament can absorb moisture from the air, which can lead to poor print quality and nozzle clogs. Store filament in a cool, dry place, preferably in sealed containers with desiccant packs. If your filament has absorbed moisture, consider using a filament dryer before printing.microfit microfit3 microfit3.0 microfit3.0 kit molex microfit3 molex microfit 3.0 microfit 3.0 series products molex microfit 3.0 series products

8. Monitor the Extruder Gear

The extruder gear feeds filament into the hot end, and any debris or wear can cause slipping or inconsistent extrusion. Regularly inspect the gear for any buildup of filament particles and clean it if necessary.microfit microfit3 microfit3.0 microfit3.0 kit molex microfit3 molex microfit 3.0 microfit 3.0 series products molex microfit 3.0 series products

9. Check Electrical Connections

Loose or corroded electrical connections can cause intermittent issues or even damage the printer. Periodically inspect all electrical connections, including those to the motors, thermistors, and power supply, to ensure they are secure.microfit microfit3 microfit3.0 microfit3.0 kit molex microfit3 molex microfit 3.0 microfit 3.0 series products molex microfit 3.0 series products

10. Perform Regular Calibration

Calibration ensures that your printer operates within the desired tolerances. This includes calibrating the X, Y, and Z axes, the extruder steps per millimeter (e-steps), and the flow rate. Proper calibration results in more accurate and dimensionally consistent prints.microfit microfit3 microfit3.0 microfit3.0 kit molex microfit3 molex microfit 3.0 microfit 3.0 series products molex microfit 3.0 series products

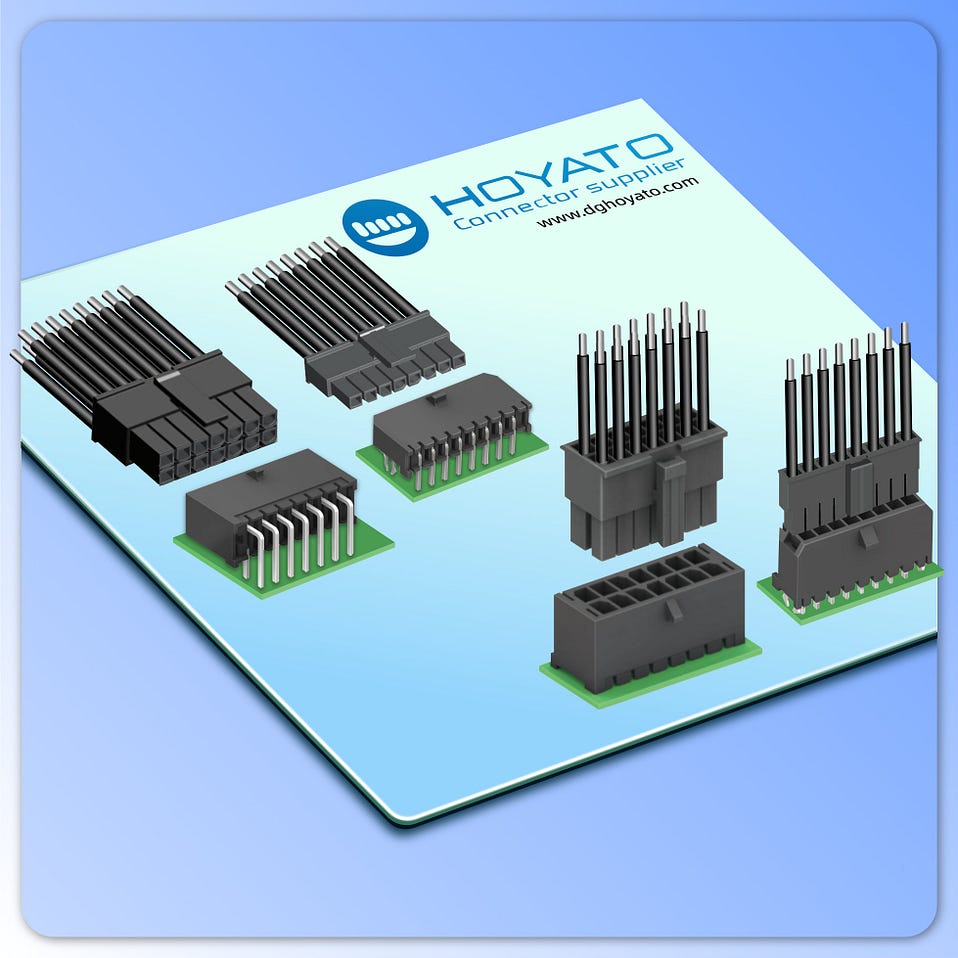

11. Inspect and Maintain Connectors (Including MicroFit 3 Connectors)

High-quality connectors, such as MicroFit 3 connectors, play a vital role in ensuring stable and reliable electrical connections in your 3D printer. These connectors are designed to handle high currents and resist vibrations, making them ideal for demanding applications.microfit microfit3 microfit3.0 microfit3.0 kit molex microfit3 molex microfit 3.0 microfit 3.0 series products molex microfit 3.0 series products

MicroFit 3 connectors, manufactured by reputable brands, are precision-engineered components that can withstand repeated plugging and unplugging without compromising their electrical integrity. They are specifically built to endure the challenging conditions inside a 3D printer, such as continuous movement, temperature changes, and potential vibrations.microfit microfit3 microfit3.0 microfit3.0 kit molex microfit3 molex microfit 3.0 microfit 3.0 series products molex microfit 3.0 series products

While these connectors may seem expensive at first glance, their long-term benefits far outweigh the initial cost. Poor-quality connectors can lead to intermittent electrical issues, which not only affect print quality but can also cause hardware damage over time. Investing in high-grade connectors like MicroFit 3 ensures that your printer operates reliably and consistently, reducing downtime and maintenance efforts.microfit microfit3 microfit3.0 microfit3.0 kit molex microfit3 molex microfit 3.0 microfit 3.0 series products molex microfit 3.0 series products

To properly maintain MicroFit 3 connectors, regularly inspect them for signs of wear or corrosion. Ensure that the connectors are firmly seated and free of dust or debris. If you notice any damage or loss of fit, consider replacing the connectors promptly to avoid future issues.microfit microfit3 microfit3.0 microfit3.0 kit molex microfit3 molex microfit 3.0 microfit 3.0 series products molex microfit 3.0 series products

For those looking to modify or upgrade their printers, using MicroFit 3 connectors can also make assembly and disassembly more convenient. Unlike direct wiring, these connectors allow for easy removal of components during repairs or upgrades, enhancing the overall user experience.microfit microfit3 microfit3.0 microfit3.0 kit molex microfit3 molex microfit 3.0 microfit 3.0 series products molex microfit 3.0 series products

Final Thoughts

Regular maintenance is key to getting the best performance and longevity out of your 3D printer. By dedicating some time to these tasks, you’ll save yourself from frustration, costly repairs, and subpar prints. Treat your 3D printer well, and it will reward you with countless hours of reliable printing.microfit microfit3 microfit3.0 microfit3.0 kit molex microfit3 molex microfit 3.0 microfit 3.0 series products molex microfit 3.0 series products

contact me: sales09@dghoyato.com